產品中心

John Deere約翰迪爾強鹿柴油發(fā)動機檢查和測量閥門與標準參數(shù)

詳細描述

John Deere約翰迪爾強鹿柴油發(fā)動機檢查和測量閥門與標準參數(shù)

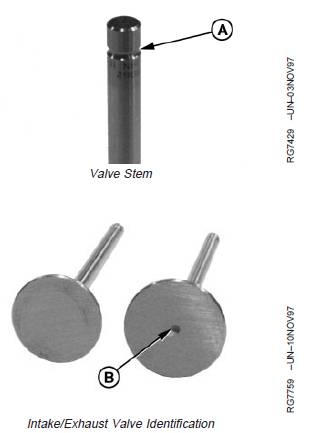

1. Clean and inspect valves, valve stems, stem tips, andretainer lock groove (A). Replace valves that are wornor damaged.

Specification

Intake Valve Head—OD 46.47—46.73 mm(1.830—1.840 in.)

Exhaust Valve Head—OD 42.37—42.63 mm(1.668—1.678 in.)

NOTE: Intake valve has a larger head OD and is alsoidentified with a dimple (B) on valve head.

A—Retainer Lock Groove

B—Dimple

2. Measure valve stem OD. Record measurements andcompare with valve guide ID. (See MEASURE VALVEGUIDES later in this group.)

Specification

Intake Valve Stem—OD 7.864—7.884 mm(0.3096—0.3104 in.)

Exhaust Valve Stem—OD 7.848—7.874 mm(0.3090—0.3100 in.)

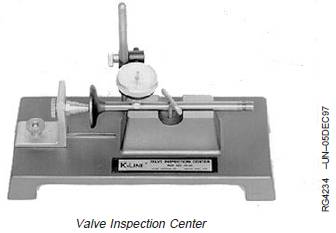

3. Using a valve inspection center, determine if valves areout of round, bent, or warped.

Specification

Valve Face—Maximum Runout(Intake and Exhaust) .............................................. 0.038 mm (0.0015 in.)

Grind Valves

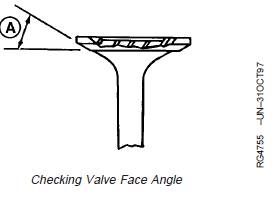

IMPORTANT: DO NOT nick valve head-to-stem radiuswhen grinding valves. A nick couldcause the valve to break. Break allsharp edges after grinding.

Reface serviceable valves to specified angle (A).

Specification

Valves—Face Angle............................................................ 29.25° ± 0.25°

A—Valve Face Angle

John Deere約翰迪爾強鹿柴油發(fā)動機檢查和清潔氣缸蓋

1. Inspect combustion face for evidence of physicaldamage, oil or coolant leakage, or gasket failure priorto cleaning the cylinder head. Repair or replacecylinder head if there is evidence of physical damage,such as cracking, abrasion, distortion, or valve seat“torching”. Inspect all cylinder head passages forrestrictions.

2. Scrape gasket material, oil, carbon, and rust fromhead. Use a powered wire brush to clean sealingsurfaces.

IMPORTANT: Be sure to remove all plugs beforecleaning head, as parts can bedamaged or destroyed by hot tanksolutions.

3. Clean cylinder head in a chemical hot tank, or withsolvent and a brush.

4. Dry with compressed air and blow out all passages.