產(chǎn)品中心

John Deere約翰迪爾強鹿4045柴油發(fā)動機氣門間隙的檢查和調(diào)整方法

詳細描述

檢查和調(diào)整氣門間隙

John Deere約翰迪爾強鹿4045 柴油發(fā)動機氣門間隙的檢查和調(diào)整方法

1. Remove rocker arm cover and crankcase ventilatortube.

IMPORTANT: Visually inspect contact surfaces ofvalve tips and rocker arm wear pads.Check all parts forexcessive wear,breakage, or cracks. Replace parts thatshow visible damage.Rocker arms that exhibit excessivevalve clearance should be inspectedmore thoroughly to identify damagedparts.

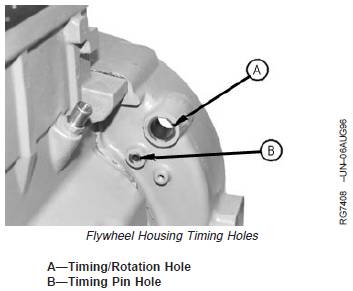

2. Remove plastic plugs or cover plate from enginetiming/rotation hole (A) and timing pin hole (B).

NOTE: Some engines are equipped with flywheelhousings which do not allow use of an engineflywheel rotation tool. These engines with straightnose crankshafts may be rotated from front noseof engine, using JDG966 Crankshaft Front/RearRotation Adapter.

3. Using JDE83 or JDE81-1 Flywheel Turning Tool, rotateengine flywheel in running direction (clockwise viewedfrom front) until No. 1 cylinder is at TDC compressionstroke. Insert JDG1571 or JDE81-4 Timing Pin inflywheel.

If No. 1 cylinder rocker arms are loose, the engine is at

No. 1 TDC compression.

If No. 1 cylinder rocker arms are not loose, rotateengine one full revolution (360°) to No. 1 TDC

4. With engine lock-pinned at TDC of No. 1 piston’scompression stroke, check valve clearance to followingspecifications. (Use sequence for 4-cylinder or6-cylinder engines as outlined on next page.)

Specification

Intake Valve Clearance Checking(Rocker Arm-to-Valve Tip)(Engine Cold)—Clearance 0.31—0.38 mm(0.012—0.015 in.)

Exhaust Valve ClearanceChecking (Rocker Arm-to-ValveTip) (Engine Cold)—Clearance 0.41—0.48 mm(0.016—0.019 in.)

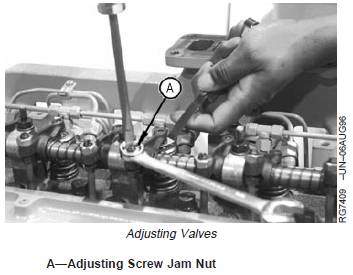

5. If valves need adjusting, use the appropriate valveclearance adjustment procedure on the next page andadjust to specifications below. Loosen the jam nut (A)on rocker arm adjusting screw. Turn adjusting screwuntil feeler gauge slips with a slight drag. Hold theadjusting screw from turning with screwdriver andtighten jam nut to specifications. Recheck clearanceagain after tightening jam nut. Readjust clearance asnecessary.

Specification

Intake Valve ClearanceAdjustment (Rocker Arm-to-ValveTip) (Engine Cold)—Clearance .................................. 0.36 mm (0.014 in.)

Exhaust Valve ClearanceAdjustment (Rocker Arm-to-ValveTip) (Engine Cold)—Clearance .................................. 0.46 mm (0.018 in.)

Specification

Rocker Arm Adjusting Screw JamNut—Torque .................................................................... 27 N•m (20 lb-ft)

6. Install rocker arm cover and crankcase ventilator tube.